Tecnosintesi Plasticizers...

... raw materials for the best performance ...

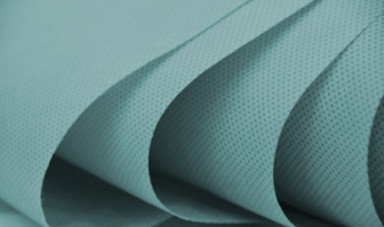

The main application for plasticizers is actually in plastics, where they are used to increase the plasticity and fluidity of the material. Plasticizers are especially used in polyvinyl chloride (PVC) application. These raw materials work by embedding themselves between the chains of polymers, spacing them apart and thus significantly lowering the glass transition temperature for the plastic; making it softer. The more plasticizer is added into the plastic, the lower its cold flex temperature will be. This means that it will be more flexible and its durability will increase as a result of it. The family of different plasticizers includes sebacates, adipates, terephthalates, dibenzoates, glutarates, phthalates, azelates, and other specialty blends. Tecnosintesi is specialized in phthalate-free plasticizers, biodegradable plasticizer of low toxicity.

| Product: | CAS Number: |

| ATBC Acetyl Tributyl Citrate | 77-90-7 |

| DAP Diallyl Phthalate | 131-17-9 |

| DOA Dioctyl Adipate | 131-17-9 |

| ESBO Epoxidated Soya Been Oil | 8013-07-8 |

| Phtalates | |

| PVA Polyvinyl Alcohol (various grades) | 58446-52-9 |

| TOTM Trioctyl Trimellitate | 3319-31-1 |

| Triacetin | 102-76-1 |

If the specialty plasticizer you are interested in is not listed here, contact us and we will source it for you.