PET/TiO2 Masterbatch

... specialty masterbatches for your application...

A masterbatch is a specific kind of pellet (plastic chips) having a well

established dosage of an active chemical ingredient or pigment and, in some cases,

some particular additives. Actually, it can be described as a concentrated mixture

of pigments and/or additives into a carrier resin.

Masterbatch is usually mixed together with a plastic polymer in a feeder, just before the extrusion

process. The advantage of a masterbatch, is to make the mixing and dosage process of all ingredients easier and to grant repetitiveness of performance.

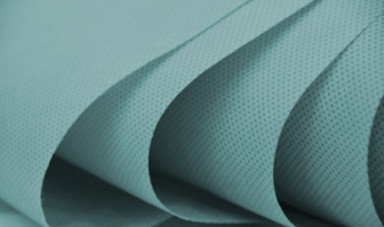

TiO2/PET Masterbatch, supplied by Tecnosintesi, is a solid functional additive for PET based

applications.

Our PET / TiO2 Masterbatch is developed to meet product performance and processing requirements that

are not met by standard grades already distributed in the market.

TiO2 percentage in the Masterbatch based on a PET carrier, can be changed in accordance with customer

requirement.

Tecnosintesi S.p.A. distributes specialty masterbatches for a wide range of applications and

engineering grade resins. Contact us to see how we can give you the best performance and

competitiveness in the market.

![]() email contact

email contact